Assuming responsibility

We make sure that everything we do is ecologically justifiable and economically meaningful. Our companies have set up a quality management system that meets this requirement. We work with state-of-the-art processing technology: Using state-of-the-art processing equipment for shredder residues, as well as high-performance shredder systems, scrap shears, rail breakers, baling presses and crushers, our employees implement innovative recycling processes effectively. Thus, we actively take responsibility for the environment and for the generations to come.Sustainability Report SRG

Closing the circle

For us, experience and innovative spirit, combined with state-of-the-art processing technology and a worldwide network give us a comprehensive range of services: This is because we cover all stages in the material recycling cycle for the almost 100% recycling of steel and metal scrap with our own operations and expert partners.

We gather the scrap in 43,000 containers, collecting from automotive and machine engineering businesses, among others. Scholz transports the pre-sorted material directly to steelworks or smelting plants by rail, truck or ship. The material to be processed is transported to our scrap yards by 750 trucks. There, the scrap is roughly sorted, precompacted and then sent to the processing plants. In a space of between 1 and 10 days, the material is processed to the form required by steelworks, smelting plants and foundries. Plants and processes are used which, for example, separate alloys back into their constituents or use mixed scrap to produce pure materials with a granularity of two millimetres. Non-metals which remain after the processing process, such as plastics, textiles and rubber are passed on to suitably specialized recyclers. Thus nothing gets wasted in this cycle.

High recycling rate according to the AltfahrzeugV end-of-life vehicle regulations

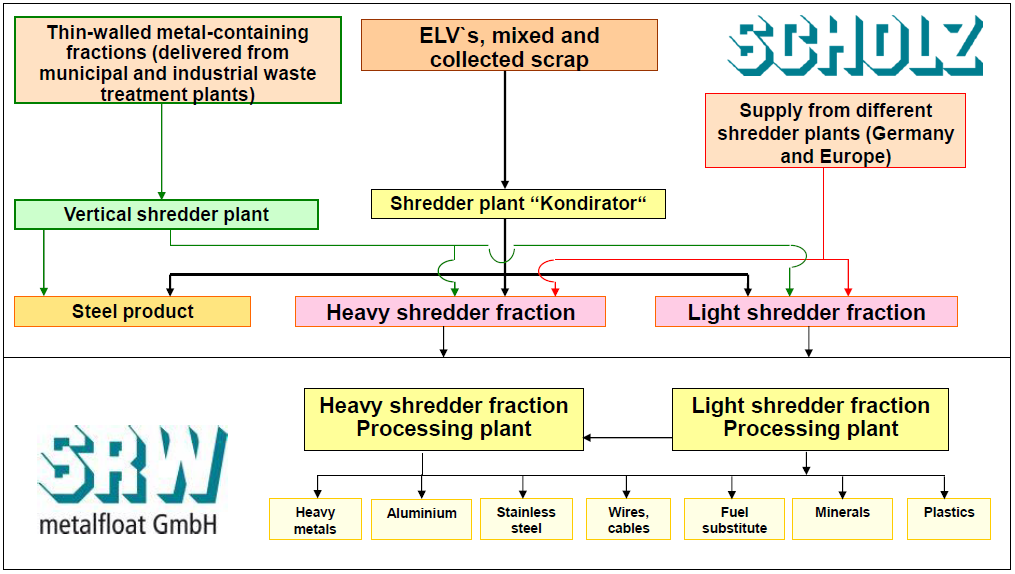

Scholz Recycling GmbH is a leader in the field of end-of-life vehicle recycling in Germany and Europe. The subsidiary SRW metalfloat GmbH in Espenhain operates systems for the treatment of shredder residue at the highest level.

The process engineering concepts developed in close cooperation with universities for the processing of light and heavy shredder fractions, as well as plastics, lead to a total recycling rate of 96.96%, according to the German End-of-Life Vehicles Ordinance.

Further areas of activity of the Espenhain engineers include recycling concepts for the preparation of end-of-life vehicles for future electromobility, as well as the processing and recycling of electrical appliances.

7 million tonnes of CO2e saved

Even though the business segments have been continually expanded, one thing has not changed over the decades: Scholz recognises its responsibility for our environment.

As a leading supplier of recycled steel and metal scrap, we make a significant contribution to the conservation of natural resources and reduction of environmental impact. For example, we saved around 7 million tonnes of CO2e emissions in 2022 by processing ferrous and non-ferrous scrap as well as by recycling wood, plastics and waste paper. These greenhouse gases would have been produced, for example, if the metal had been obtained from primary raw materials instead of from scrap.

In addition, the extraction and production processes associated with primary raw materials are very energy-intensive. The energy that is invested in recycling a recyclable material is often a fraction of the energy required for new extraction. The preparation of iron and metal scrap, for example, requires only ten percent of the energy required for the production of primary raw materials.

Recycling metals is purely a win-win situation. Scrap from steel and non-ferrous metal can be recycled as often as required without any loss of quality. The fact that our processed products are not inferior to those made from primary raw materials, is something we are constantly proving.